Mastering Ice Cream Overrun for Enhanced Quality and Profitability

Ice cream overrun is a fundamental concept in the ice cream manufacturing process that directly influences the final product’s texture, quality, and economic viability. Understanding and controlling overrun—the percentage of air incorporated into ice cream during its production—is crucial for any ice cream maker looking to perfect their craft.

Air affects the mouthfeel and density of ice cream and plays a significant role in determining its volume and, therefore, profitability.

By mastering the science of overrun, manufacturers can produce ice cream that is not only deliciously creamy but also cost-effective, maximizing profit margins while maintaining high-quality standards.

This guide will explore the intricacies of ice cream overrun and its impact, providing you with the knowledge to refine your production techniques and enhance the overall appeal of your ice cream offerings.

You may also like

- All Posts

- Blog

- Company news

- Equipment

- Recipe

- Training

Categories

What is Ice Cream Overrun? Understanding Its Critical Role in Frozen Desserts

Ice cream overrun refers to the air incorporated into ice cream during production. This key factor significantly affects ice cream, gelato, and sorbet’s texture, volume, and overall sensory experience. In the ice cream industry, managing overrun is essential for ensuring product quality, controlling production costs, and maximizing profitability.

The Significance of Overrun in Ice Cream Production: Overrun is measured as the percentage increase in volume caused by the air whipped into the ice cream mix during the freezing process. It is a crucial element because it determines the final product’s body, texture, and palatability. Ice cream with too little overrun may come off as overly dense and hard, while too much air can make it taste insubstantial and quick to melt.

Air’s Impact on Texture and Volume: The role of air in ice cream is more than just filling space; it creates the creamy, smooth texture that consumers love. A typically lower overrun of 25-30% for gelato maintains a dense, intensely flavorful experience, aligning with traditional Italian standards. Standard scoop ice cream usually features a higher overrun, around 50-60%, which offers a lighter texture and extends the volume, increasing the number of servings per batch and thus influencing price and profitability. Soft serve ice cream enjoyed for its light, fluffy texture, can have an overrun as high as 80%, especially in varieties dispensed from high-air mix pump machines.

By precisely controlling overrun, ice cream artisans and manufacturers can tailor the textural characteristics of their products to meet consumer expectations and balance cost efficiency. Understanding and applying the principles of overrun effectively allows for the production of ice creams that taste better and present a more appealing mouthfeel, ensuring consumer satisfaction and repeat business.

The Science Behind Overrun: Air’s Integral Role in Ice Cream Texture and Volume

Understanding the science behind overrun is crucial for anyone producing ice cream and other frozen desserts. Overrun refers to the air whipped into the ice cream mix during freezing. This technique profoundly impacts the final product’s texture, density, and volume.

How Air is Incorporated into Ice Cream: During the freezing process, ice cream mixtures are simultaneously churned to incorporate air, a method known as dynamic freezing. This not only cools the mixture but also introduces air bubbles trapped by the fat, proteins, and stabilizers in the mix. The efficiency of this air incorporation depends mainly on the type of ice cream maker used, the churning speed, and the mix’s composition. The air bubbles that form help lighten the ice cream’s density, giving it a soft, creamy texture that enhances its sensory appeal.

Effects of Air on Texture and Density: The amount of air added during churning, measured as overrun, directly affects the texture of ice cream. A higher overrun means more air and a lighter, fluffier texture, while a lower overrun results in a denser, more decadent ice cream. The right balance can enhance mouthfeel and palatability, making the dessert more enjoyable.

Typical Air Content Percentages by Frozen Dessert Type:

Gelato: Known for its dense texture and intense flavour, gelato typically has a lower overrun of about 25-30%. This low amount of air results in a thicker consistency that emphasizes the rich flavours of the gelato.

Standard Scoop Ice Cream: It often has an overrun of 50-60%, creating a balance that provides a creamy texture without diluting the flavor too much.

Soft Serve Ice Cream: This dessert can vary significantly in overrun, generally between 30-80%. Soft serve machines that use a gravity feed system typically produce ice cream with an overrun of 30-35%, while those with a pump system might reach 60-80%, creating an extremely light and airy product.

Understanding these dynamics allows ice cream producers to precisely control product quality and can help tailor offerings to meet specific consumer preferences. By mastering the science of overrun, manufacturers can optimize the textural properties of their ice cream, ensuring each variety—from gelato to soft serve—delivers the desired consumer experience in terms of both taste and texture.

Calculating Overrun: A Step-by-Step Guide to Perfecting Ice Cream Texture

Accurately calculating the overrun in ice cream ensures consistent product quality and texture. Overrun, the percentage of air volume incorporated into ice cream significantly affects the final product’s creaminess, mouthfeel, and profitability. Here’s a detailed step-by-step guide on measuring and calculating overrun to help you master this crucial aspect of ice cream production.

Step 1: Measure the Weight of the Liquid Mix. Start by placing an empty container on a scale and zeroing out the weight. Pour your liquid ice cream mix into the container until it reaches the brim, and then weigh it. Note this weight as it represents the total weight of the fluid mix before freezing and air incorporation.

Step 2: Weigh the Frozen Product After the ice cream has been churned and frozen, clean and dry the same container used previously. Fill this container with the frozen ice cream, smoothing the top with a straight edge to ensure evenness. Weigh the container with the frozen product and record this weight, which shows the weight of the ice cream after the air has been incorporated.

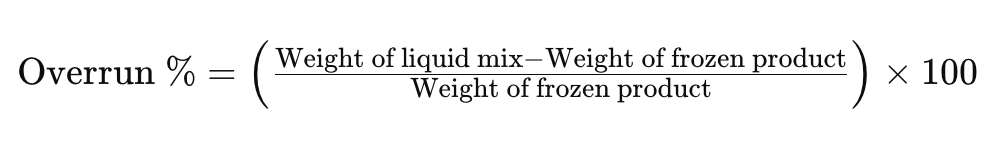

Step 3: Calculate the Percentage of Overrun To determine the overrun percentage, use the following formula:

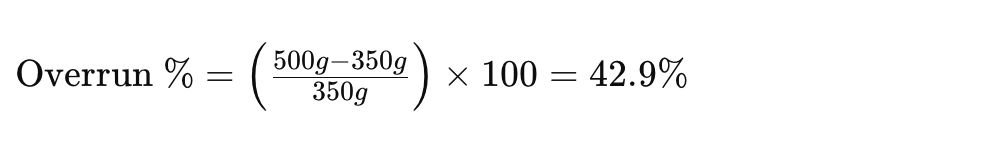

For example, if the weight of the liquid mix is 500g and the weight of the frozen product is 350g, the calculation would be:

This percentage indicates how much air is incorporated into the product, impacting its volume and texture.

Factors Affecting Overrun: Keep in mind that several variables can influence the overrun calculation, including the condition of the ice cream machine, the specific recipe or formulation used, and the type of machine (gravity or pump). Understanding these factors can help you adjust the process to achieve your ice cream’s desired overrun and consistency.

Impact of Overrun on Ice Cream Quality and Profitability

Understanding the impact of overrun on ice cream quality and profitability is crucial for any ice cream producer. The level of overrun—the amount of air incorporated into the ice cream during production—plays a significant role not only in defining the texture and mouthfeel of the product but also in influencing its economic efficiency and market appeal.

Effect of Overrun on Ice Cream Quality: Overrun directly affects ice cream’s texture and sensory qualities. A higher overrun generally results in a lighter, airier texture, perceived as refreshing and delightful in soft serve or premium ice creams. However, too much air can lead to a product that feels insubstantial or melts too quickly, which might not satisfy consumer expectations for richer, creamier desserts. Conversely, a lower overrun yields a denser and creamier product, often preferred in artisanal gelatos or luxury ice cream brands, where the emphasis is on rich flavors and a decadent mouthfeel.

Economic Implications of Overrun: From a business perspective, managing overrun effectively can lead to significant cost savings and impact pricing strategies:

Cost Efficiency: A higher overrun means more product volume from the same amount of raw ingredients. This can decrease the cost per unit, allowing producers to price competitively or increase profit margins.

Pricing Strategy: The level of overrun can influence pricing. Premium brands often feature lower overrun, promoting quality and richness as selling points and justifying higher prices.

Consumer Perception: Overrun influences consumers’ value perception, as they may equate denser, less aerated ice creams with higher quality and be willing to pay more for them. In contrast, products with higher overrun may be viewed as being of lower premium. However, they offer a light, playful texture that some market segments prefer.

Balancing Overrun for Optimal Outcomes: Finding the right balance of overrun that aligns with your brand identity and target market preferences is key. It allows you to optimize production costs while meeting or exceeding consumer expectations. For example, luxury ice cream brands might opt for lower overruns to emphasize quality and artisan craftsmanship, whereas commercial brands focused on volume sales might use higher overruns to maximize yield and profitability.

Ultimately, strategic management of overrun enhances the quality and appeal of your ice cream and positions your product appropriately in the marketplace, affecting both consumer satisfaction and business profitability. Producers can create ice creams that delight consumers and deliver on economic goals by understanding and controlling overrun.

Optimizing Overrun: Achieving the Perfect Balance for Exceptional Ice Cream

Achieving the optimal overrun percentage is crucial for producing high-quality ice cream that meets specific consumer preferences and market demands. This section provides essential tips on fine-tuning the overrun to enhance the texture, volume, and overall appeal of various ice cream products. Understanding the factors influencing overrun will help you adjust your production process for the best results.

Tips for Achieving Optimal Overrun:

Understand Your Product Goals: Different ice cream products require different overrun levels. For example, luxury artisan gelato may benefit from a lower overrun to maintain a dense, rich texture. Soft serve might need a higher overrun for a lighter, fluffier feel. Define your product’s most essential sensory attributes and adjust the overrun accordingly.

Monitor Your Mix Composition: The ingredients in your ice cream mix can significantly affect how much air the mixture can incorporate. Higher fat and protein contents generally stabilize air incorporation, facilitating higher overrun without sacrificing texture. Adjusting the levels of stabilizers and emulsifiers can also help control the overrun to achieve the desired creaminess and body.

Calibrate Your Equipment: The type of ice cream machine you use (e.g., batch freezer vs. continuous freezer, gravity vs. pump models) dramatically influences the amount of air that can be whipped into the mix. Regularly calibrate your machines and ensure they are in optimal working condition to maintain consistent overrun levels.

Factors Influencing Overrun:

Machine Type and Configuration: The design of your ice cream machine, whether it uses a pump system for higher overrun or gravity feeding for lower overrun, plays a pivotal role. Understanding the mechanics of your equipment will allow you to leverage its capabilities to your advantage.

Condition of Equipment: Well-maintained machines achieve more consistent overrun percentages. Regular maintenance checks and servicing are vital to ensure that the machine performs optimally, maintaining the quality and consistency of your product.

Recipe Formulation: The composition of your ice cream base impacts how well air is incorporated. Recipes formulated with appropriate proportions of fats, proteins, sugars, and stabilizers are more likely to achieve the desired overrun and textural properties.

By considering these factors and implementing the tips provided, ice cream manufacturers can optimize overrun to meet production goals and exceed consumer expectations. Proper overrun management leads to a superior product in the competitive ice cream market. Whether developing new recipes or seeking to improve existing ones, focusing on overrun optimization will undoubtedly elevate the quality of your ice cream offerings.

Mastering Overrun for Superior Ice Cream Quality

Understanding and controlling ice cream overrun is fundamental for any ice cream maker looking to produce a product that tastes great and presents with an appealing texture and optimal profitability. Overrun affects everything from the creamy texture and mouthfeel of your ice cream to the economic aspects of production, such as cost efficiency and consumer price points.

The Value of Overrun Knowledge: Mastering the overrun process enables you to tailor the texture and volume of your ice cream to meet specific market demands and personal preferences. Whether you aim to create a dense, rich gelato or a light and airy soft serve, controlling the amount of air incorporated during the freezing process is key to achieving your desired product quality.

Applying Overrun Insights in Production: We encourage all ice cream producers, from artisanal creators to large-scale manufacturers, to use the insights from this guide in their production processes.

Experimenting with different overrun percentages and understanding how various factors such as machine type, mix composition, and operational settings affect overrun can significantly improve product quality and business outcomes.

By fine-tuning your overrun, you can enhance the sensory qualities of your ice cream, making it more appealing to consumers and more competitive in the market. Whether you are just starting out or looking to refine your existing recipes, focusing on overrun optimization is a step towards creating exceptional ice cream that stands out for its quality and craftsmanship.

Continue exploring and experimenting with overrun adjustments in your ice cream production. Please share your experiences and outcomes with us and the wider ice cream-making community. Let’s learn and grow together, enhancing our techniques to craft the perfect ice cream. For more detailed information and advanced tips, revisit our comprehensive ice cream production and overrun management resources.

- All Posts

- Blog

- Company news

- Equipment

- Recipe

- Training

Discover the best sugar for ice cream recipes. Learn the best sugar practices for perfect ice cream.

Discover the best sugar for ice cream recipes. Learn the best sugar practices for perfect ice cream.

Discover the best sugar for ice cream recipes. Learn the best sugar practices for perfect ice cream.

The secrets of ice cream overrun to improve texture, quality, and profitability. Tips for optimizing overrun in ice cream production.

High-quality whole milk and cream serve as the foundation of your ice cream but significantly influence its flavor, texture, and…

These easy-to-make crumbs bring the fun of a birthday cake to any treat. Learn how to whip up this playful…